APPLICATIONS

NUCLEAR APPLICATIONS

The nuclear power industry is one of the most complex in terms of technologies and quality requirements.

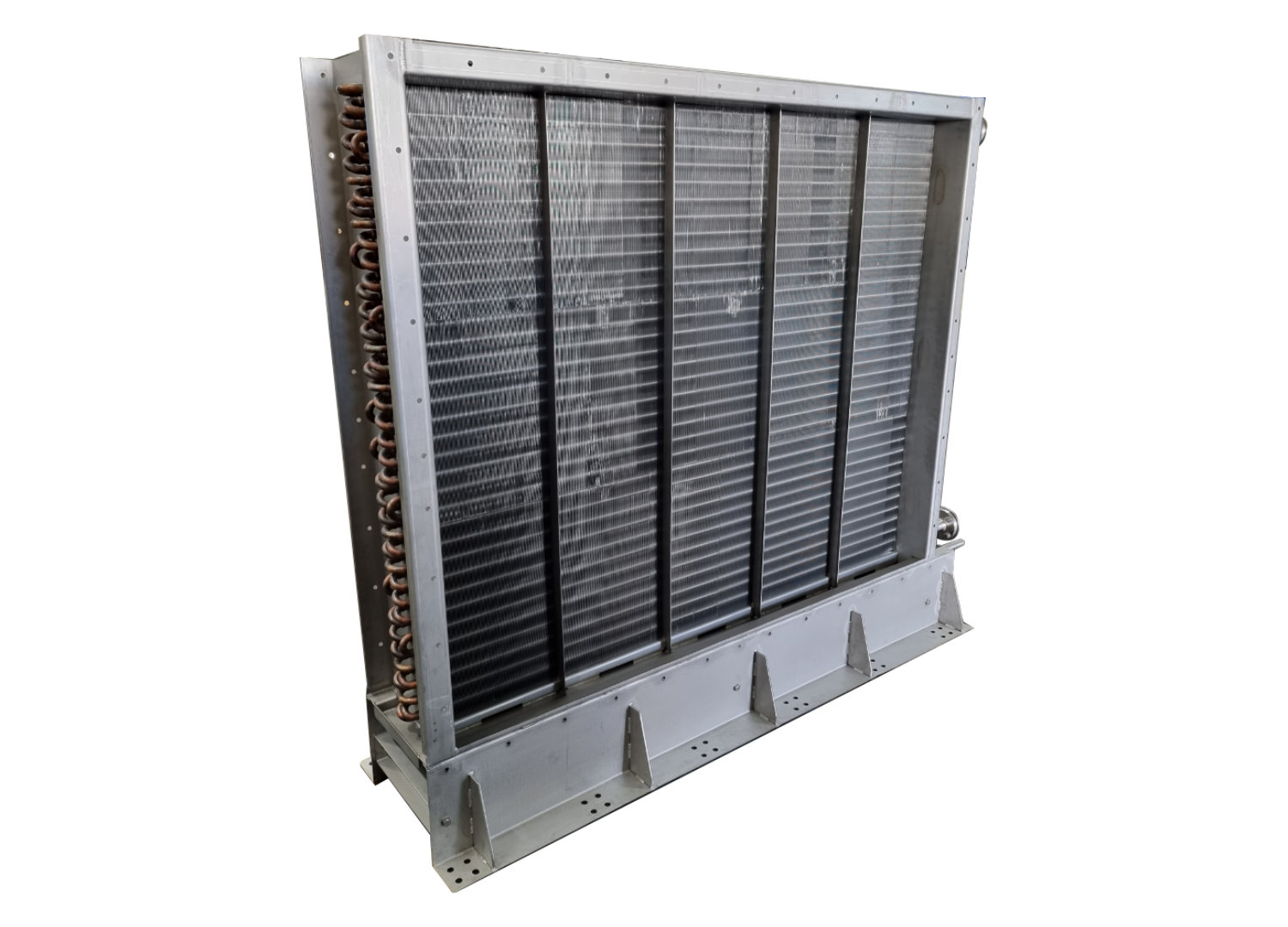

FACO has extensive knowledge in delivering heat exchangers and drycoolers for many different industrial applications. We are committed to supply safety related items that satisfy the special demands of the nuclear power industry.

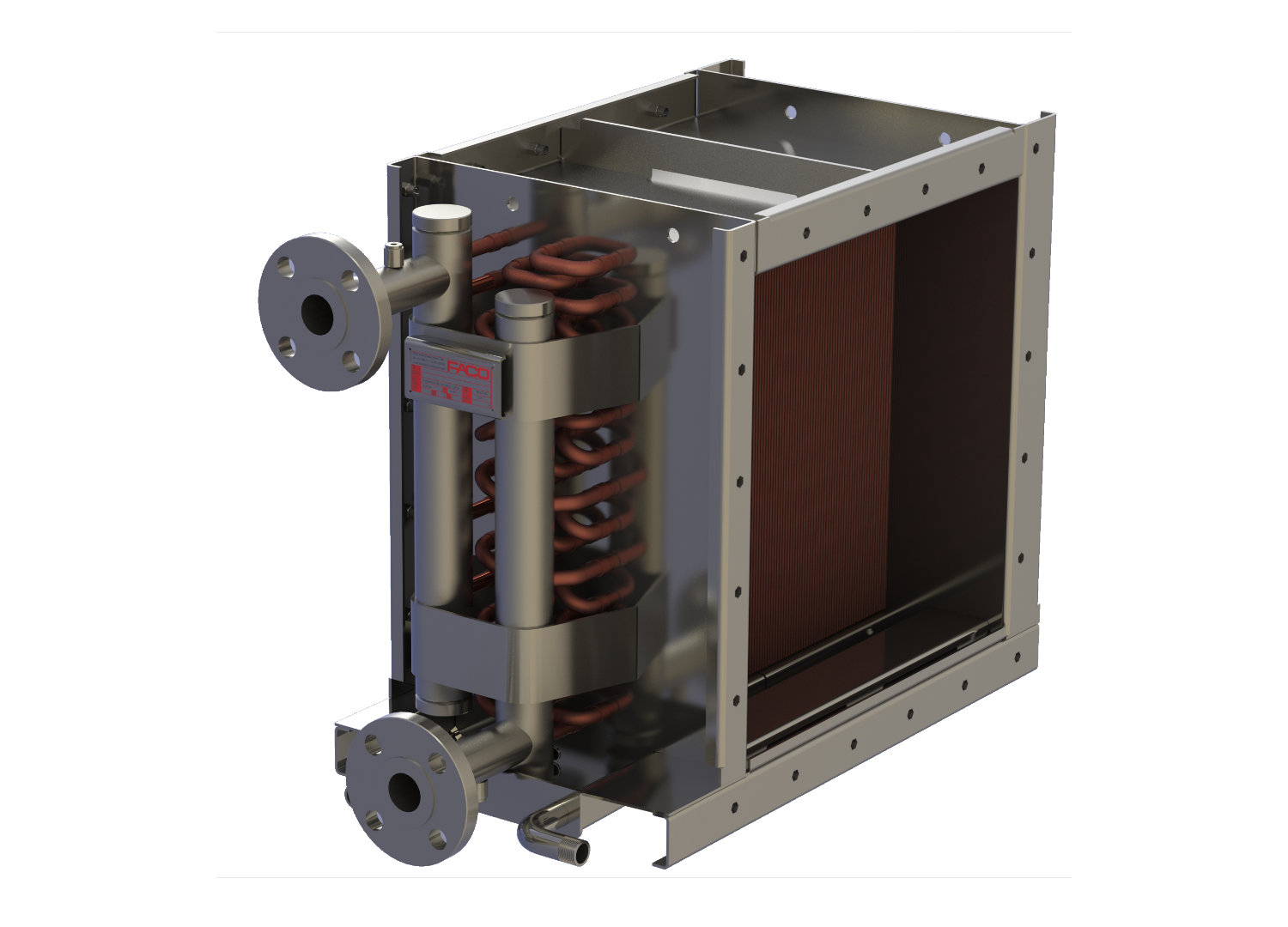

FACO can design and manufacture its heat exchangers according to AFCEN’s RCC-M code, concerning the mechanical components designed and manufactured for pressurised water reactors (PWR) for systems which require temperature control:

- Motor/generator coolers

- Ventilation heat exchangers

- Transformer oil coolers

- Radiators

Typical applications include emergency and/or normal cooling of control rooms, switch gear, pump rooms, and process air.

The product’s design is customized according to the site specific requirements and conditions.

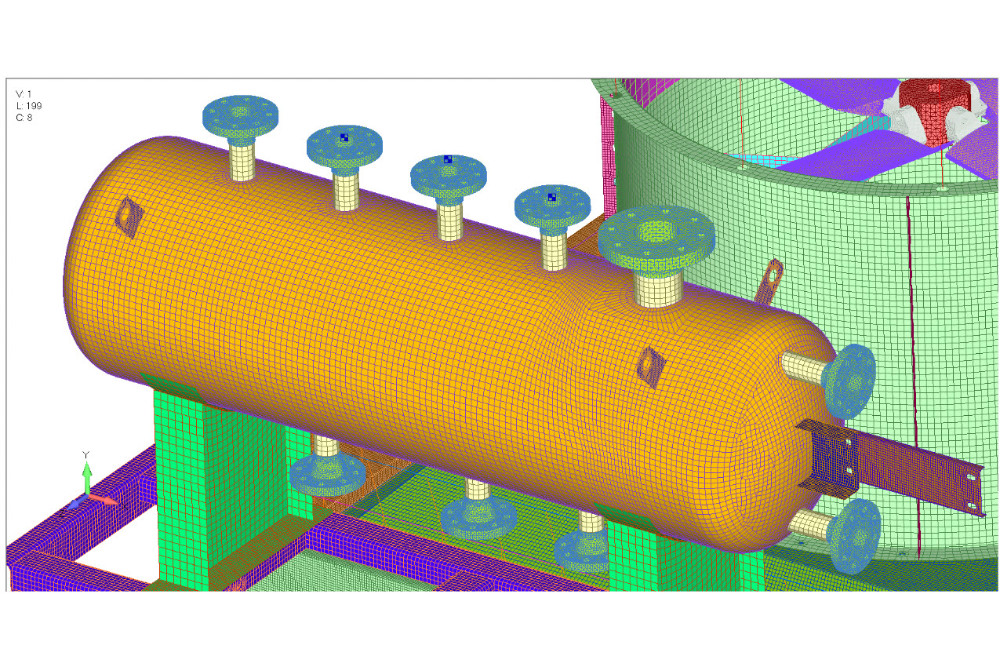

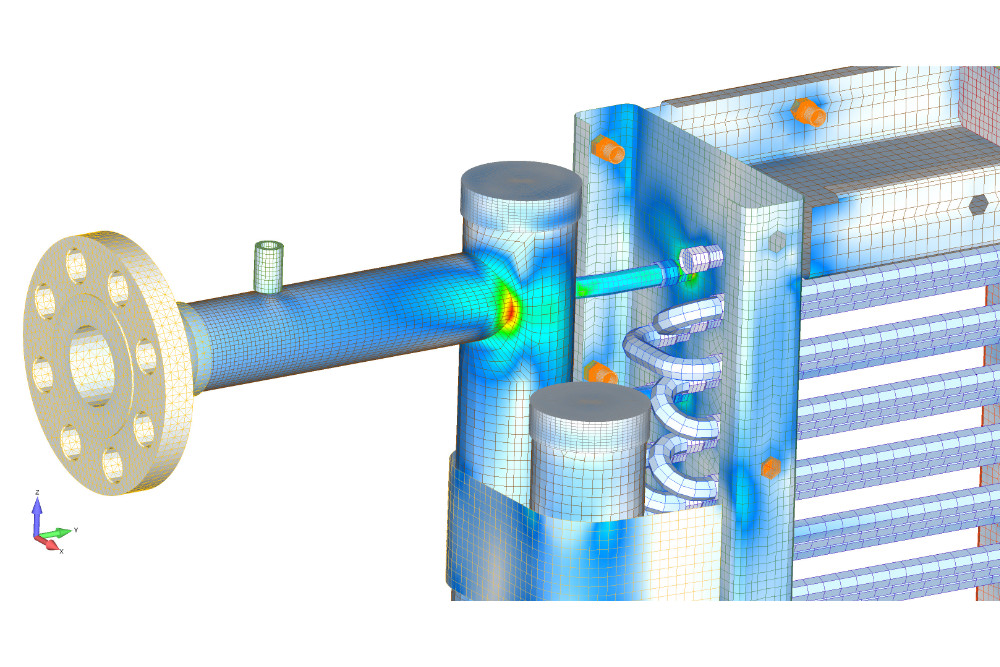

FACO can validate the product strength calculations with ASME or EN standards. More extensive load evaluations, as seismic assessment and design, shock analysis and design, fatigue assessment are performed by Finite Element Analysis (FEA). Project specific reports can be issued according to the requirements.

The manufacturing process is monitored according to the project specific inspection and test plan (ITP).

A pneumatic pressure test is performed on all products. A wide range of NDT are also available for standard or specific requirements.

Nuclear power experience

| Project | Seismic class | Year | |

|---|---|---|---|

| MOCHOVCE | SLO | CLASS 1A | 2011 |

| GRAVELINES / SAINT LAURENT / TRICASTIN / BLAYAIS / CHOOZ / CHINON |

FR | SC1+SC2 | 2014 |

| EPR FLAMANVILLE | FR | SC1+SC2 | 2015 / 2015 |

| BUGEY | FR | SC1 | 2014 / 2018 |

| LOOVISA | FIN | CLASS 1E | 2015 / 2016 |

| SAINT-ALBAN / FLAMANVILLE / PALUE / CATTENOM / PENLY / GOLFECH / BELLEVILLE / NOGENT |

FR | SC1+SC2 | 2016 |

| CENTRALE NUCLEAIRE DU PARC | SC2 | 2016 | |

| NOGENT / BELLEVILLE / CATTENOM FLAMANVILLE / PENLY / GOLFECH |

FR | SC1+SC2 | 2016 / 2017 |

| MARCOULE | FR | CLASS 1E | 2017 / 2018 |

| PALUEL / FLAMANVILLE SANT-ALBAN |

FR | SC1+SC2 | 2018 |

| TIHANGE | BE | CLASS 1E | 2018 |

| MELOX | Chusclan-FR | CLASS 1 | 2020 |

| RJH | Cadarache-FR | CLASS 1E | 2019 / 2021 |

| HPC | Hinkley Point-UK | SC1+SC2 | 2021 / 2025 |

| BLAYAIS / CATTENOM / CIVAUX CRUAS / GRAVELINES / TRICASTIN CHOOZ / GOLFECH / NOGENT PALUEL / PENLY / SAINT-ALBAN BELLEVILLE / BUGEY / CHINON DAMPIERRE / SAINT-LAURENT |

FR | CF | 2021 / 2025 |

Design and certifications

FACO operates on a ISO 9001:2015 certified quality management system. The thermo-dynamic design is carried out with the assistance of a in-house-developed software, based on parameters measured in the Company’s thermo-dynamic testing laboratory, built in accordance with ASHRAE standards. FACO holds the AHRI certification for the performance of the water exchangers. Conformity to CE directives in force is verified for all the production.

The structural calculation can be carried out according to the ASME VIII div.1 code, or in accordance with other codes on request. FACO has welding and brazing procedures and operators qualified to ASME IX and EN 9606, EN 15614, EN 13585, EN 13134 available.

Heat exchangers can be designed and manufactured in anti-seismic or shockproof execution. Design and manufacturing of ASME BPVC “U” designator certified products.

- ISO 9001 certified QMS

- Design according to ASME VIII div.1, EN 13445

- Nuclear applications design according to RCC-M

- PED Modules H/H1, up to Cat. IV equipment

- ASME BPVC “U” designator certificate

- CRN certification

- UL/CSA compliance

- ATEX certification

- AHRI Std. 410 Performance certification

- Welding/Brazing ASME IX and EN 9606, EN 15614, EN 13585, EN 13134

- NDT operators EN ISO 9712, SNT-TC-1A, ASME V

- Zero Emission Electricity & Natural Gas EN 14064 certification

CONTACT US

If you want more information about our services, fill out the form below,

we will replay as soon as possible

Address

Via SS. Trinità, 16A

28040 Varallo Pombia (NO)

Italy

Phone

(+39) 0321 968 211

info@faco.it