PRODUCTS

HVAC/R COILS

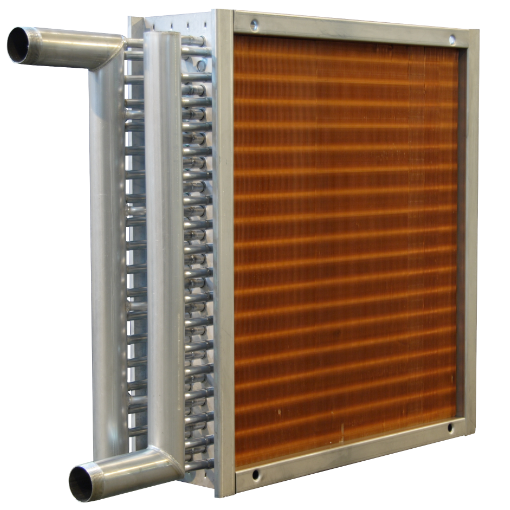

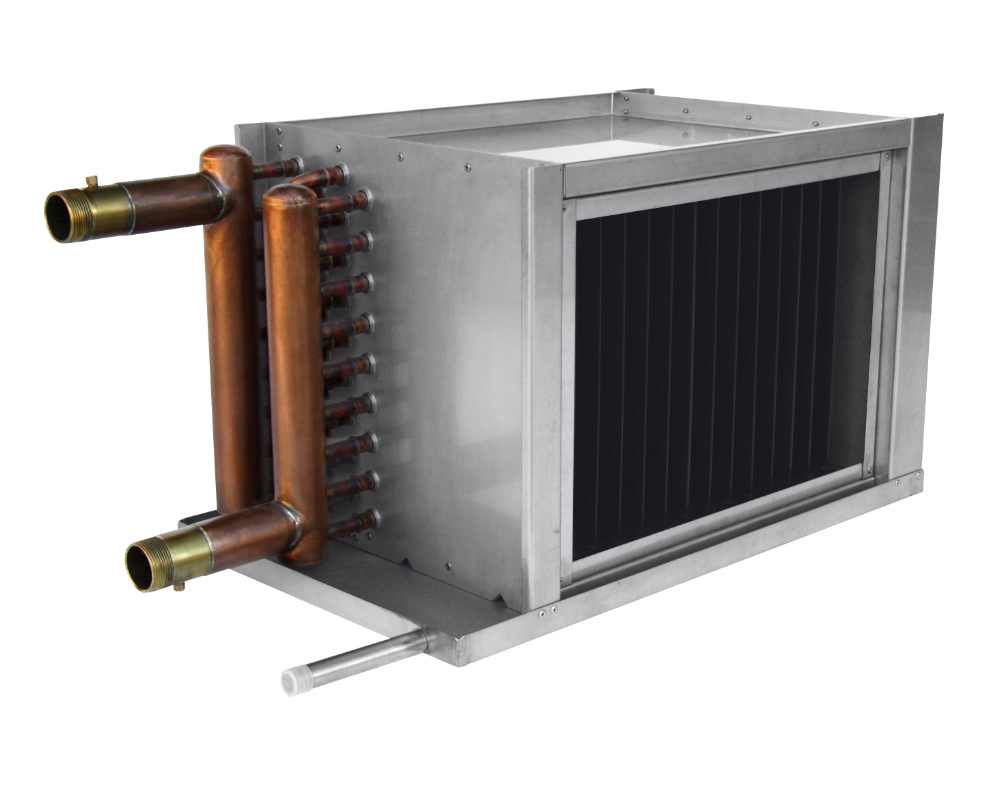

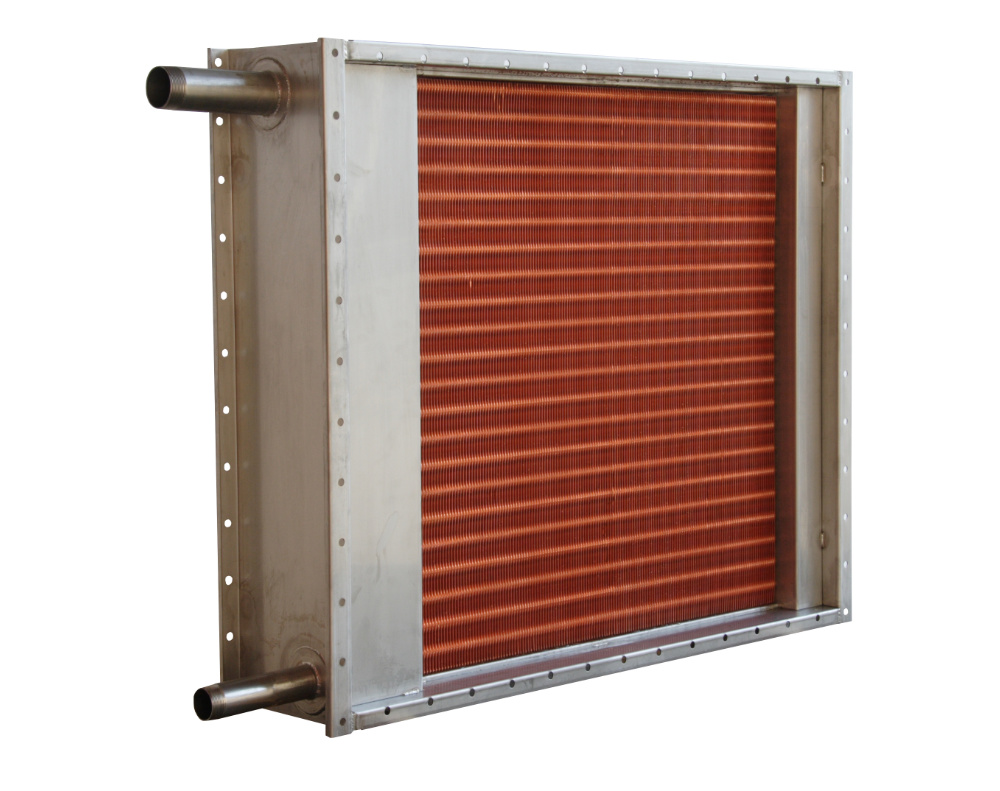

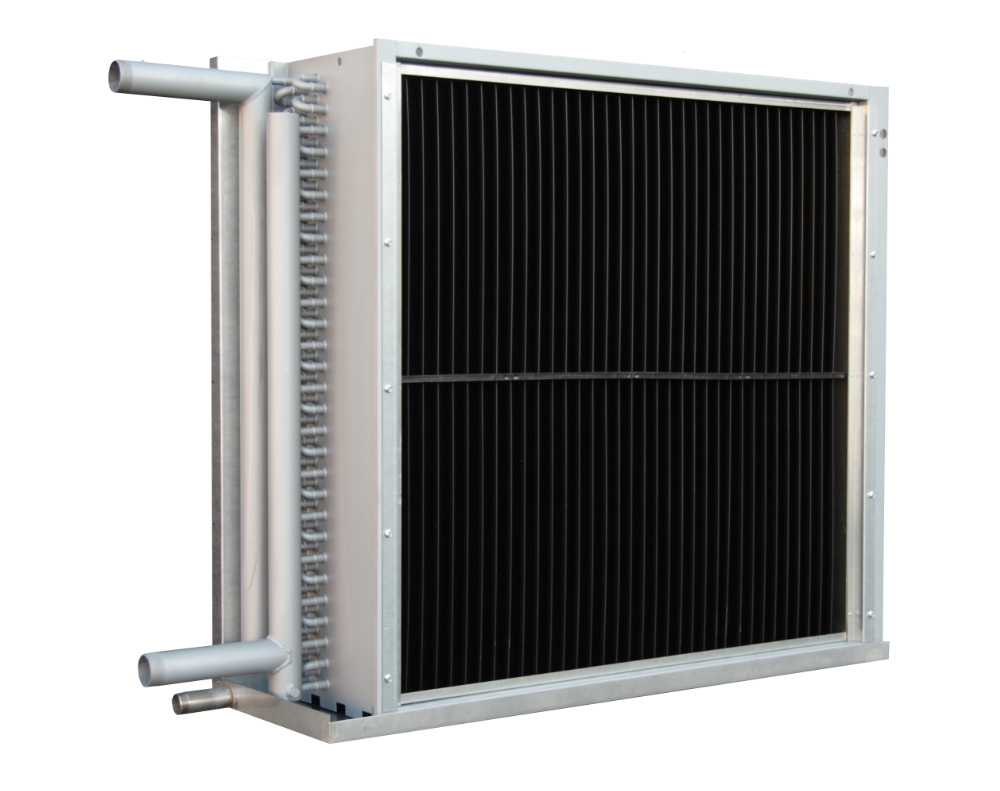

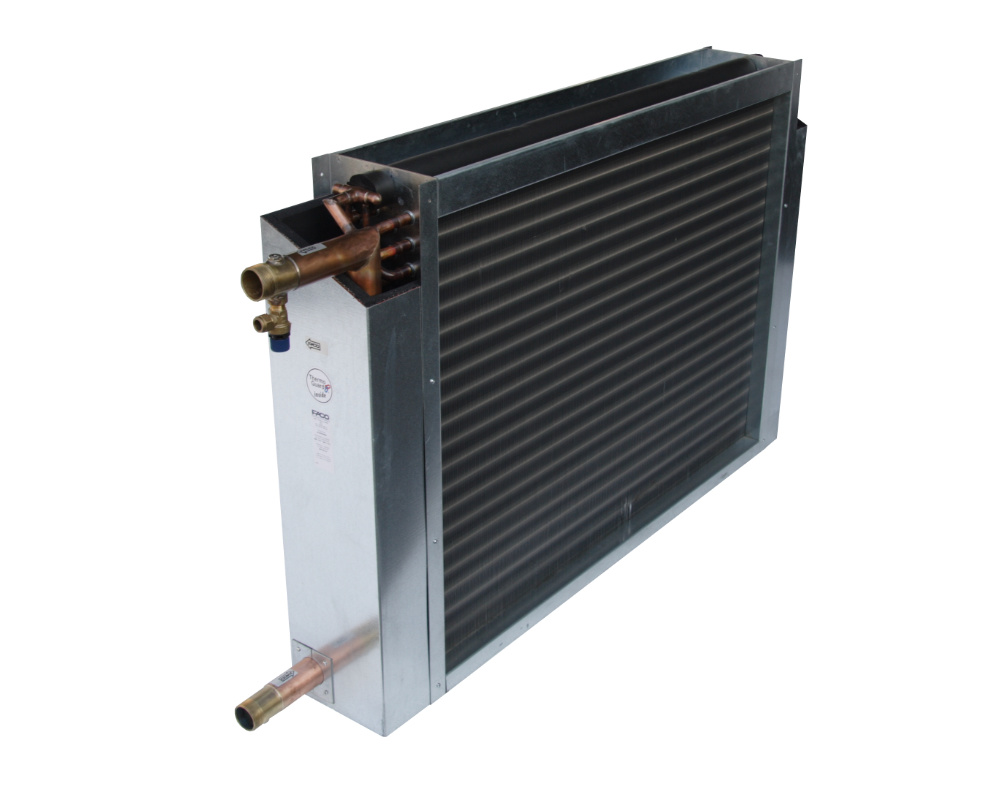

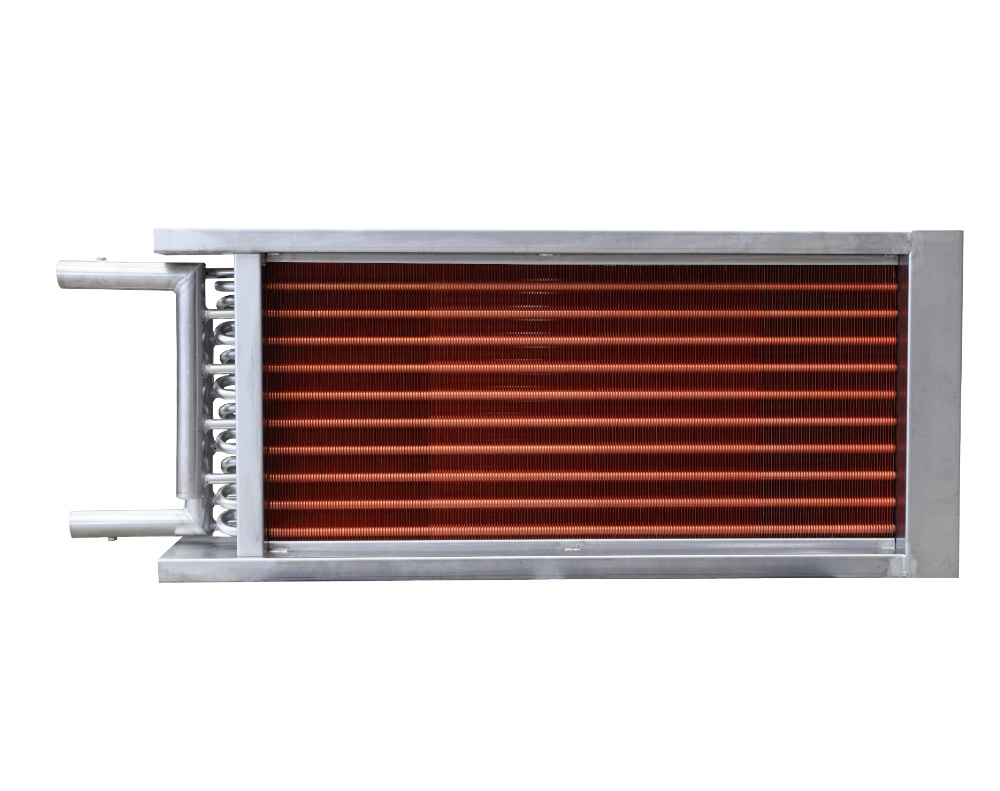

The wide choice of material, patterns and accessories, together with the high flexibility of its production, allows FACO to design and manufacture custom made finned block coils for all HVAC & Refrigeration applications and for a broad selection of fluids: water, glycol, oil, steam, ammonia, CO2, other refrigerant fluids, hydrocarbons, technical gases, etc.

Whatever your requirements FACO will provide the exact coil for your application, with flexibility of custom engineered circuiting, fin spacing, header configurations and materials.

Our range of products for HVAC/R applications includes the following finned block heat exchangers:

- Water, glycol, oil heating and cooling coils

- Refrigerant evaporators

- Refrigerant condensers

- Steam coils

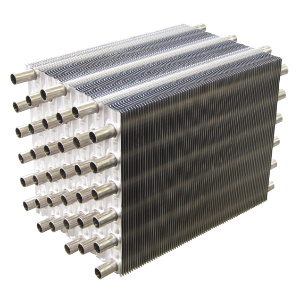

Air to liquid heat exchangers, typically consisting of multiple rows and circuits with pipe headers and fix return bends.

AHRI certified coils are available for air to water applications.

Special arrangements:

- Removable plugs: with plugs instead of traditional return bends. The plugs can be removed to clean the inside of the heat exchanger tubes to restore them to like new performance. For applications where fluids with sediment, or other contaminants are present and routine cleaning is required to keep the system working at peak performance.

- Box headers: with tubesheets and removable box headers instead of traditional pipe headers and return bends. The box headers can be removed to clean the inside of the heat exchanger tubes to restore them to like new performance. For applications where fluids with high level of sediment, or other contaminants and routine cleaning is required to keep the system working at peak performance.

- Bare tubes: with bare tubes, without fins. For applications in contaminated environments or where very low air side pressure drop is required.

- Split core: multiple sections coils for easy installation and replacement. These coils can be made with more than one core to to fit the coil into tight spaces.

- Airtight: the housing is fully welded to prevent inside process air and outside air from coming into contact with each other.

Direct Expansion (DX) evaporator coils, typically consisting of multiple rows and circuits with suction pipe header, distributors, capillary tubes and fix return bends. Interlaced, face split, row split circuits types.

Special arrangements:

- Airtight: the housing is fully welded to prevent inside process air and outside air from coming into contact with each other.

condenser coils for use with most refrigerants, typically consisting of multiple rows and circuits with pipe headers and fix return bends. Various circuiting options, including sub-cooling circuits. Interlaced, face split, multi-row circuits types.

Special arrangements:

- Airtight: the housing is fully welded to prevent inside process air and outside air from coming into contact with each other.

For heating applications in AHUs. Opposite or same end connections, horizontal, horizontal-sloped and vertical tubes.

Special arrangements:

- Airtight: the housing is fully welded to prevent inside process air and outside air from coming into contact with each other.

Heat recovery

In addition to multi-coil systems with conventional coils, FACO offers heat pipe heat exchangers for heat recovery.

The heat pipe heat exchangers are used in heat recovery applications to cool the incoming fresh air in air conditioning applications. They can transport large quantity of heat with very small temperature difference between evaporator and condenser sections.

They can transfer the heat without any moving parts so that the heat pipe is calm, noise-free, maintenance-free, and highly dependable. Heat pipe heat exchangers could be employed as run-around coils in air conditioning systems for enhanced dehumidification and cooling.

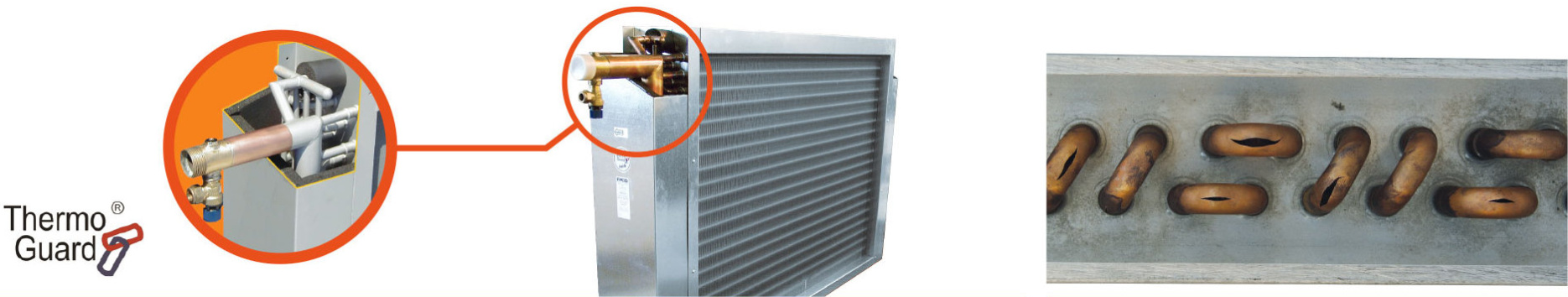

Thermoguard®

The freezing-proof solution.

Based on the principle that it is not the ice itself that causes the coils to break, but it is the increasing pressure of the water trapped in the bends when the centre of the fin block starts to freeze, the ThermoGuard® system allows for this pressure to be discharged through a secondary circuit connecting all the bends to a safety valve.

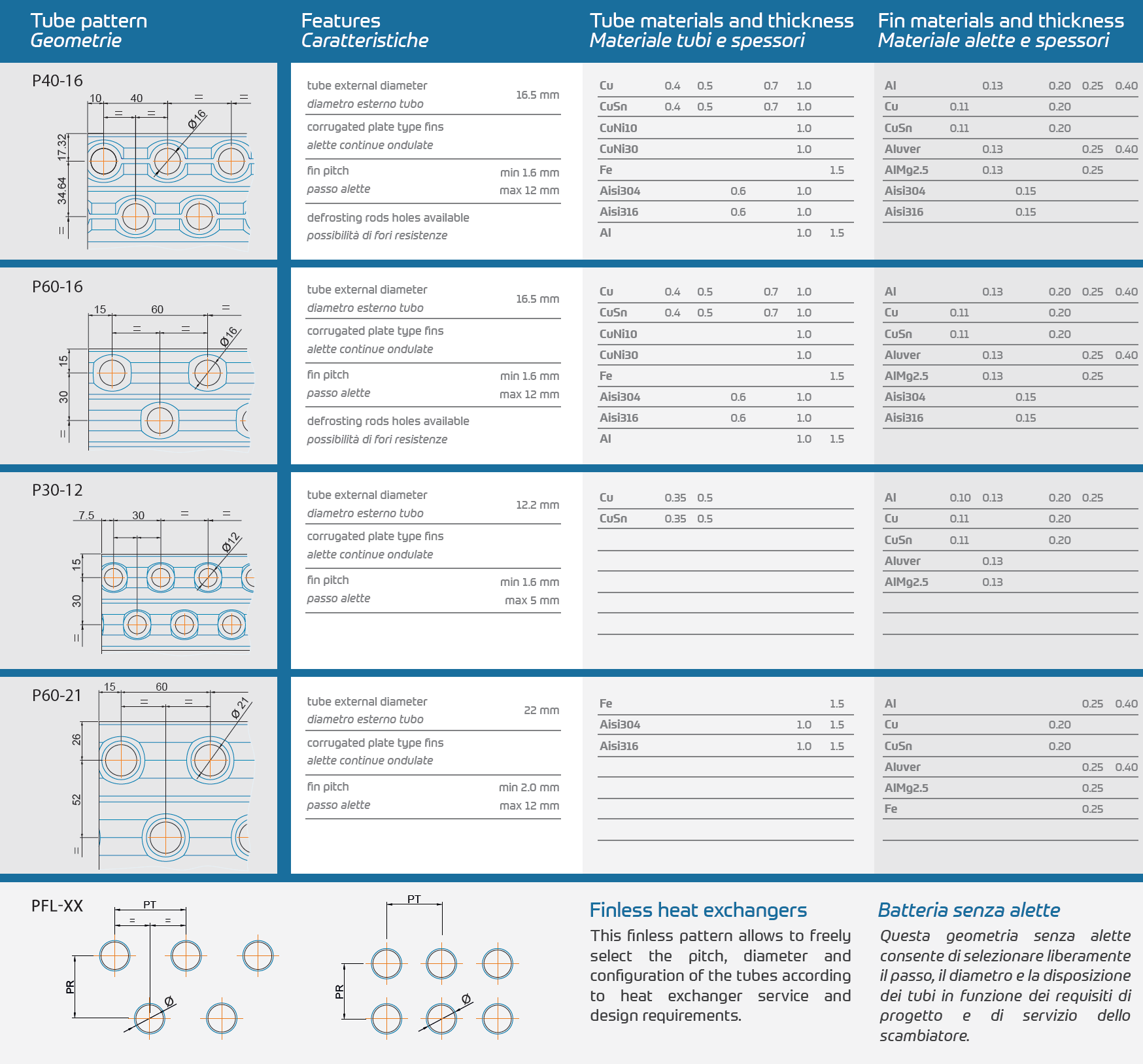

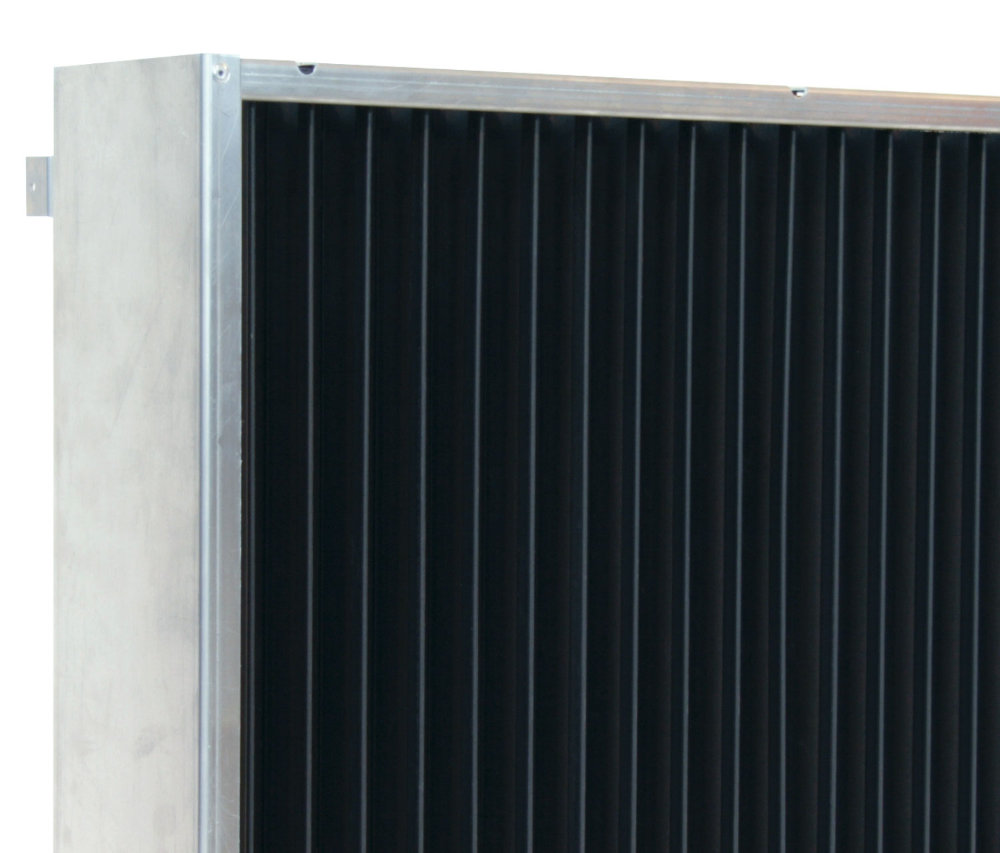

Finned block details

Finned block is composed of tubes mechanically expanded into self-spacing collars die-formed on the fins, which have a waved profile studied in FACO’s research laboratory, with the aim at the efficiency of the heat exchanger to get the best cost/performance ratio.

Accessories and special features

Headers

Materials, arrangement and connection side can be combined according to customer request. Connections are equipped with standard joints such as flanges or threads, or any other type of special connection if required. Drain and vent plugs are supplied as standard.

Materials: carbon steel, stainless steel, copper, cupronickel, aluminium.

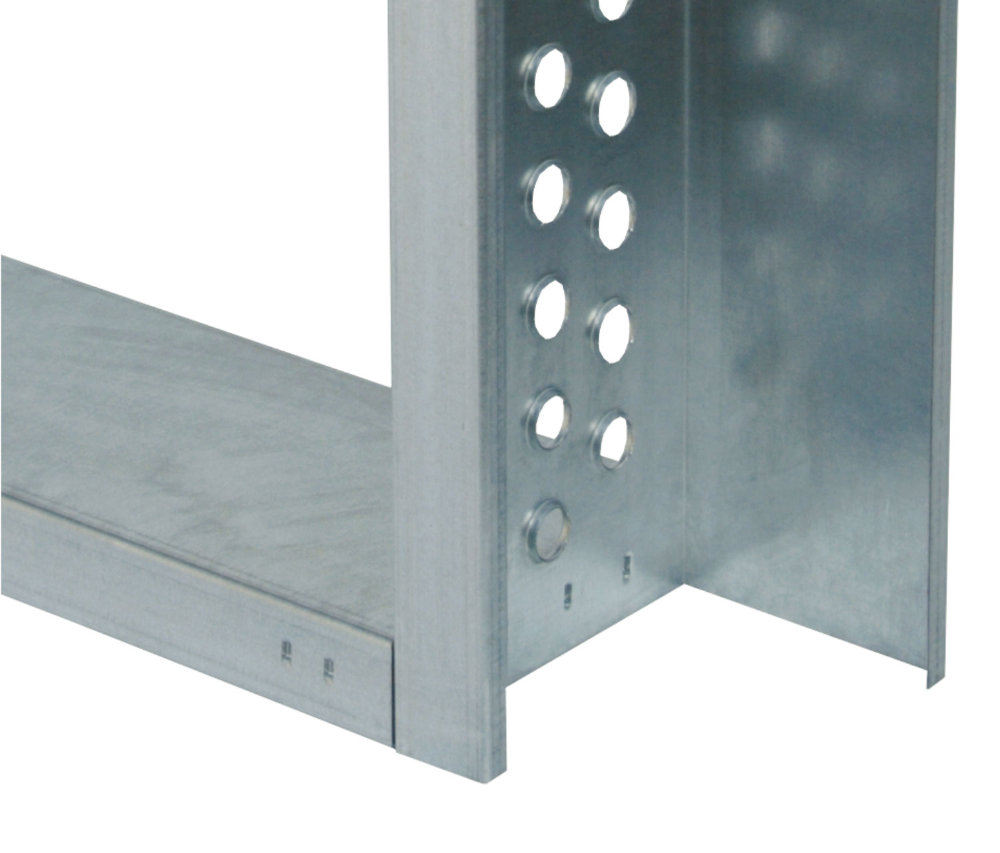

Frame

Sized according to the dimensions specified by the client, it can be delivered with integrated drip trays and drop eliminators. Closing plates and special profiles can be supplied for a better integration of the heat exchanger in the plant.

Materials: galvanized steel, carbon steel, stainless steel, aluminium, copper.

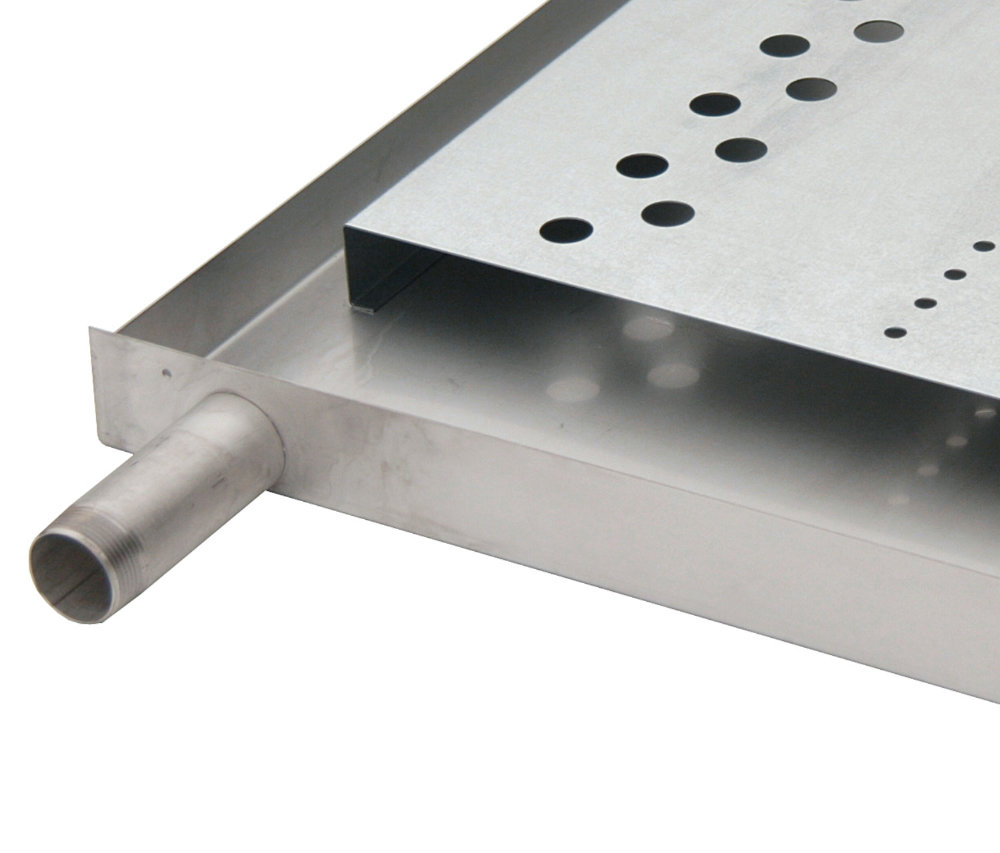

Drip trays

Installed or integrated in the lower part of the exchangers, or even at an intermediate height, they are available for duct mounting or for installation inside units. The position of the condensate drain connections can be defined according to customer request. They are available also in an airtight version, for duct mounting.

Materials: galvanized steel, stainless steel, aluminium, copper.

Drop eliminators

Installed to avoid condensate carry-over in case of high speed of air in connection with dehumidification, they can be supplied in various materials according to working conditions.

Materials: PPTV, aluminium, stainless steel.

Airtight execution

When it is necessary to isolate the flow through the fins from the external ambient, solutions with various grades of tightness can be adopted, that range from a simple sealing of the passages connecting the duct with the ambient, to a fully welded airtight construction.

Defrosting systems

In refrigeration treatments or wherever frost formation on the finned block is foreseen, the exchanger can be equipped with defrosting systems such as electrical heating rods and hot water rain or spray devices; evaporators can be delivered with a hot gas defrosting system.

Protective treatments

Particular environmental and operational conditions may require stronger protection both for the exchange surfaces and the structures. The right combination of base material and coating can guarantee the exchanger’s reliability and longevity, even in aggressive environments.

Surface treatments: tinning – polyurethane paint – hot dip galvanizing – cataphoresis – Heresite® – Rilsan® – Blygold® – Fin Guard Silver®.

Design and certifications

FACO operates on a ISO 9001:2015 certified quality management system. The thermo-dynamic design is carried out with the assistance of a in-house-developed software, based on parameters measured in the Company’s thermo-dynamic testing laboratory, built in accordance with ASHRAE standards. FACO holds the AHRI certification for the performance of the water exchangers. Conformity to CE directives in force is verified for all the production.

The structural calculation can be carried out according to the ASME VIII div.1 code, or in accordance with other codes on request. FACO has welding and brazing procedures and operators qualified to ASME IX and EN 9606, EN 15614, EN 13585, EN 13134 available.

Heat exchangers can be designed and manufactured in anti-seismic or shockproof execution. Design and manufacturing of ASME BPVC “U” designator certified products.

- ISO 9001 certified QMS

- Design according to ASME VIII div.1, EN 13445

- Nuclear applications design according to RCC-M

- PED Modules H/H1, up to Cat. IV equipment

- ASME BPVC “U” designator certificate

- CRN certification

- UL/CSA compliance

- ATEX certification

- AHRI Std. 410 Performance certification

- Welding/Brazing ASME IX and EN 9606, EN 15614, EN 13585, EN 13134

- NDT operators EN ISO 9712, SNT-TC-1A, ASME V

- Zero Emission Electricity & Natural Gas EN 14064 certification

CONTACT US

If you want more information about our services, fill out the form below,

we will replay as soon as possible

Address

Via SS. Trinità, 16A

28040 Varallo Pombia (NO)

Italy

Phone

(+39) 0321 968 211

info@faco.it